THE CHOICE OF A MECHANICAL WATCH

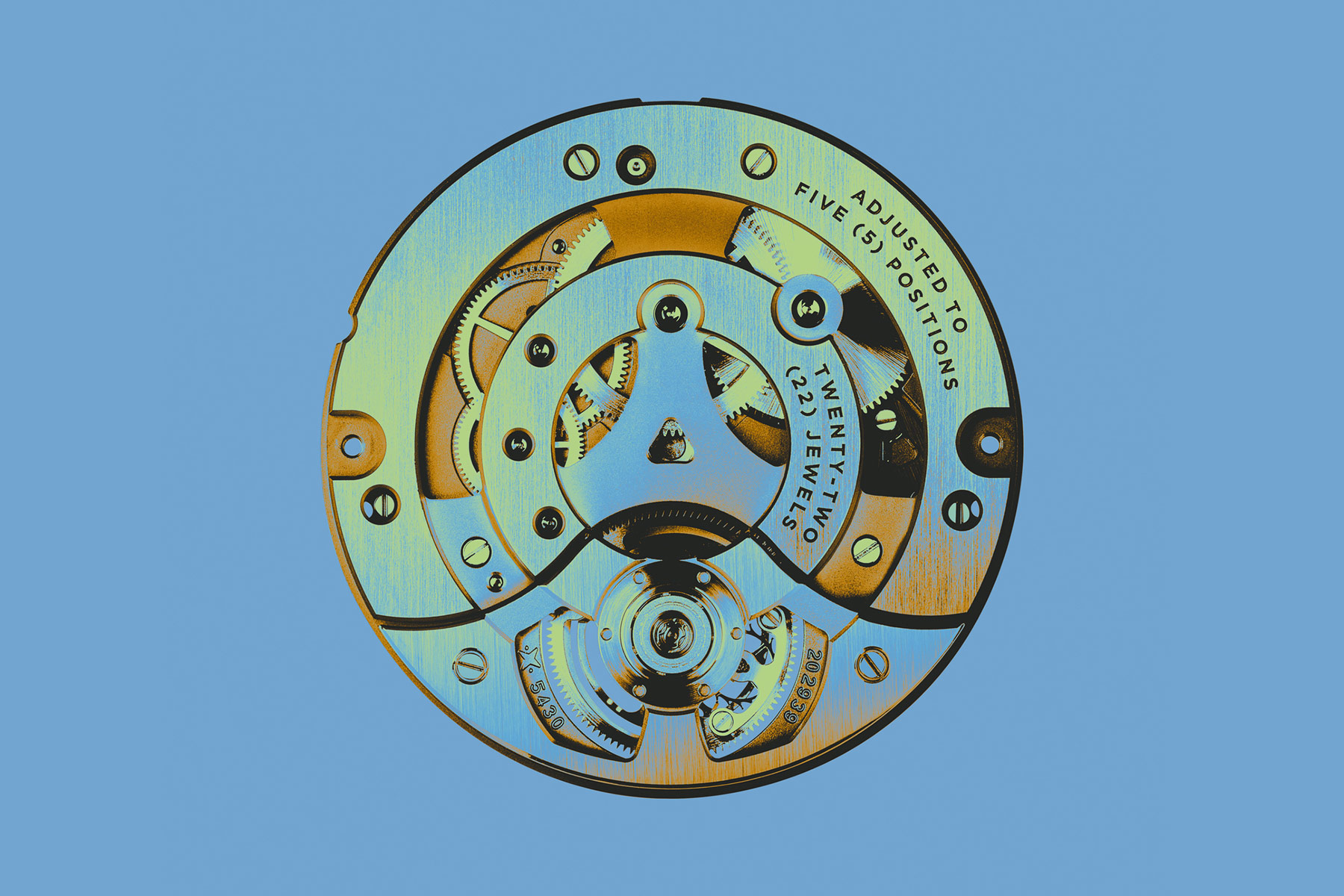

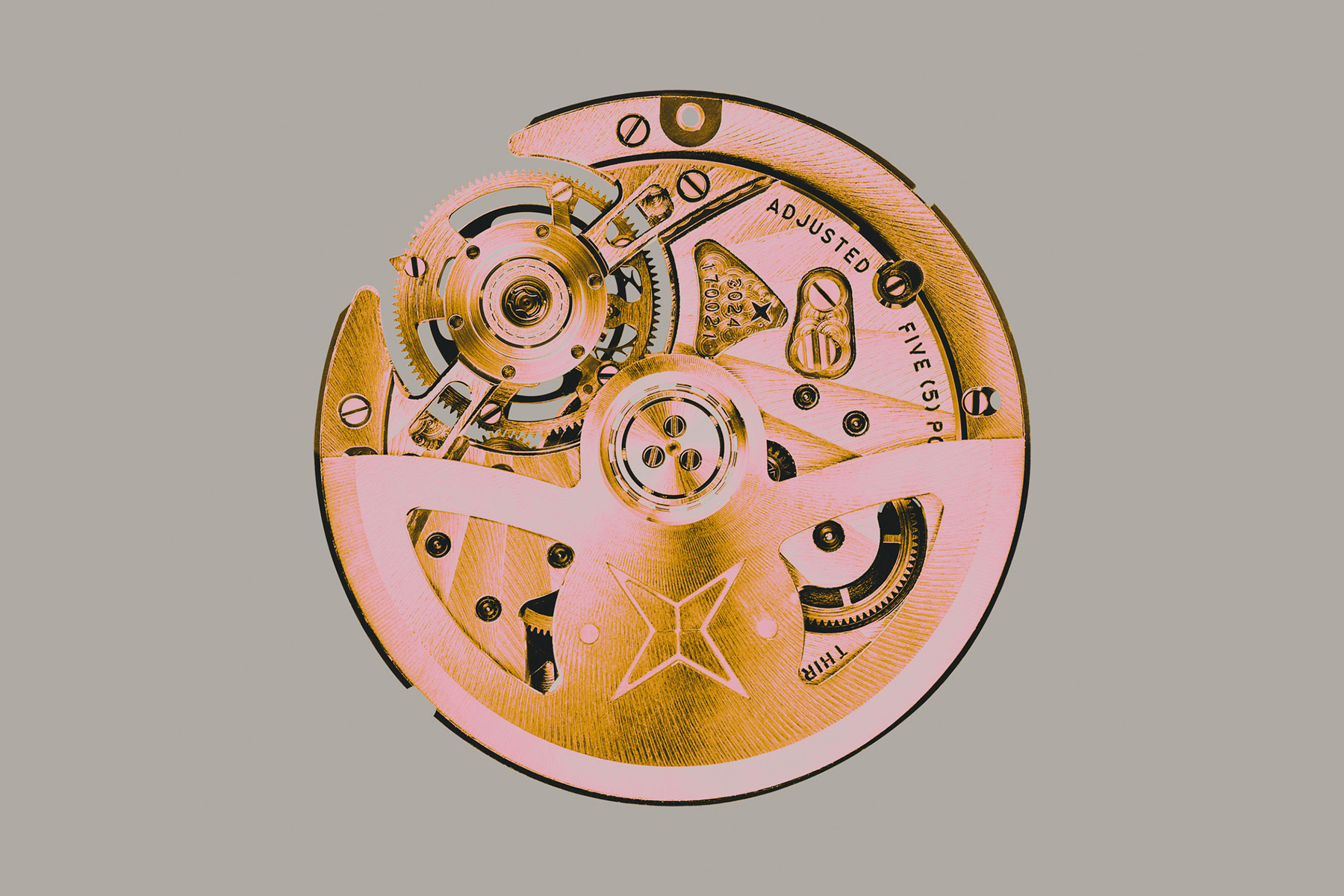

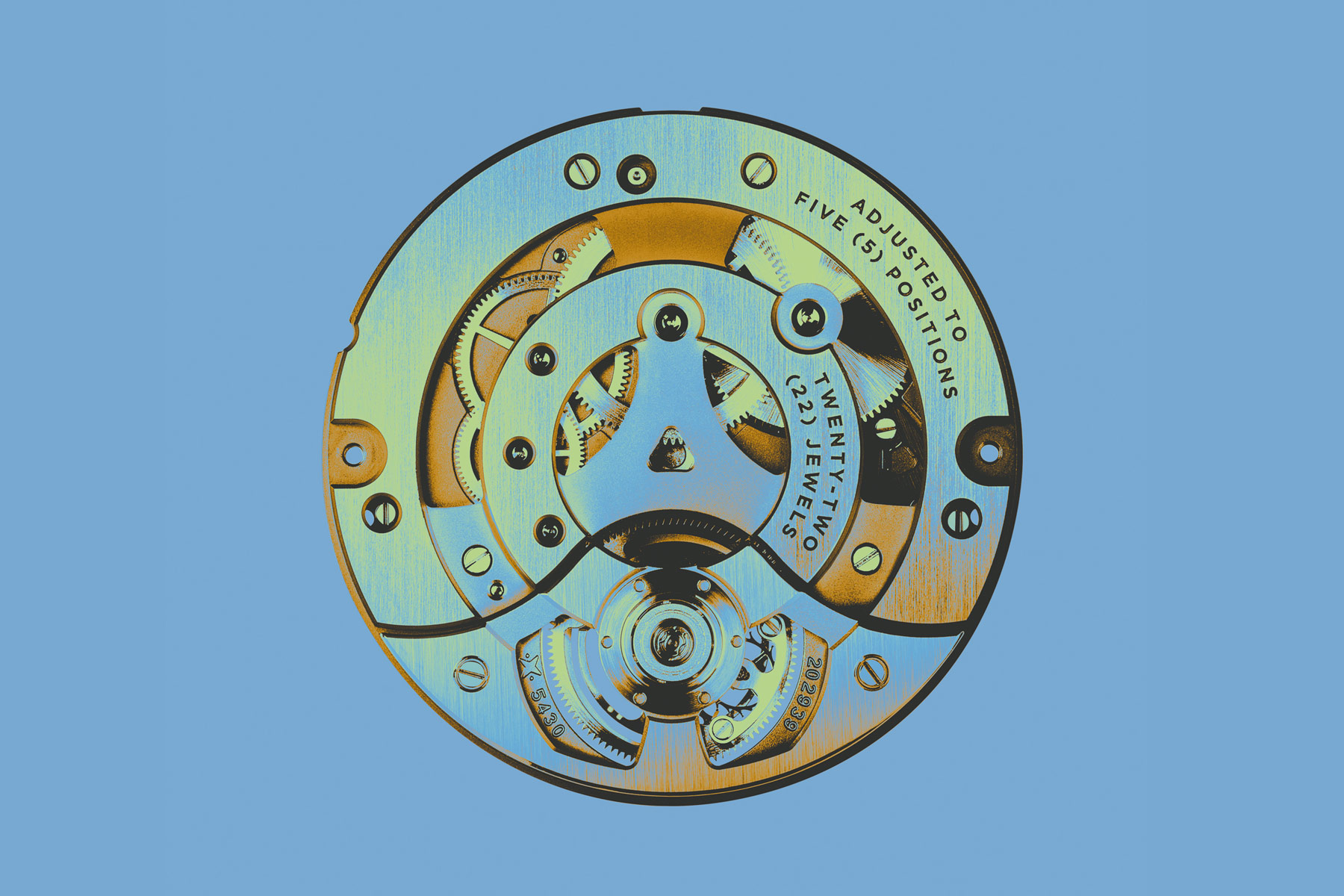

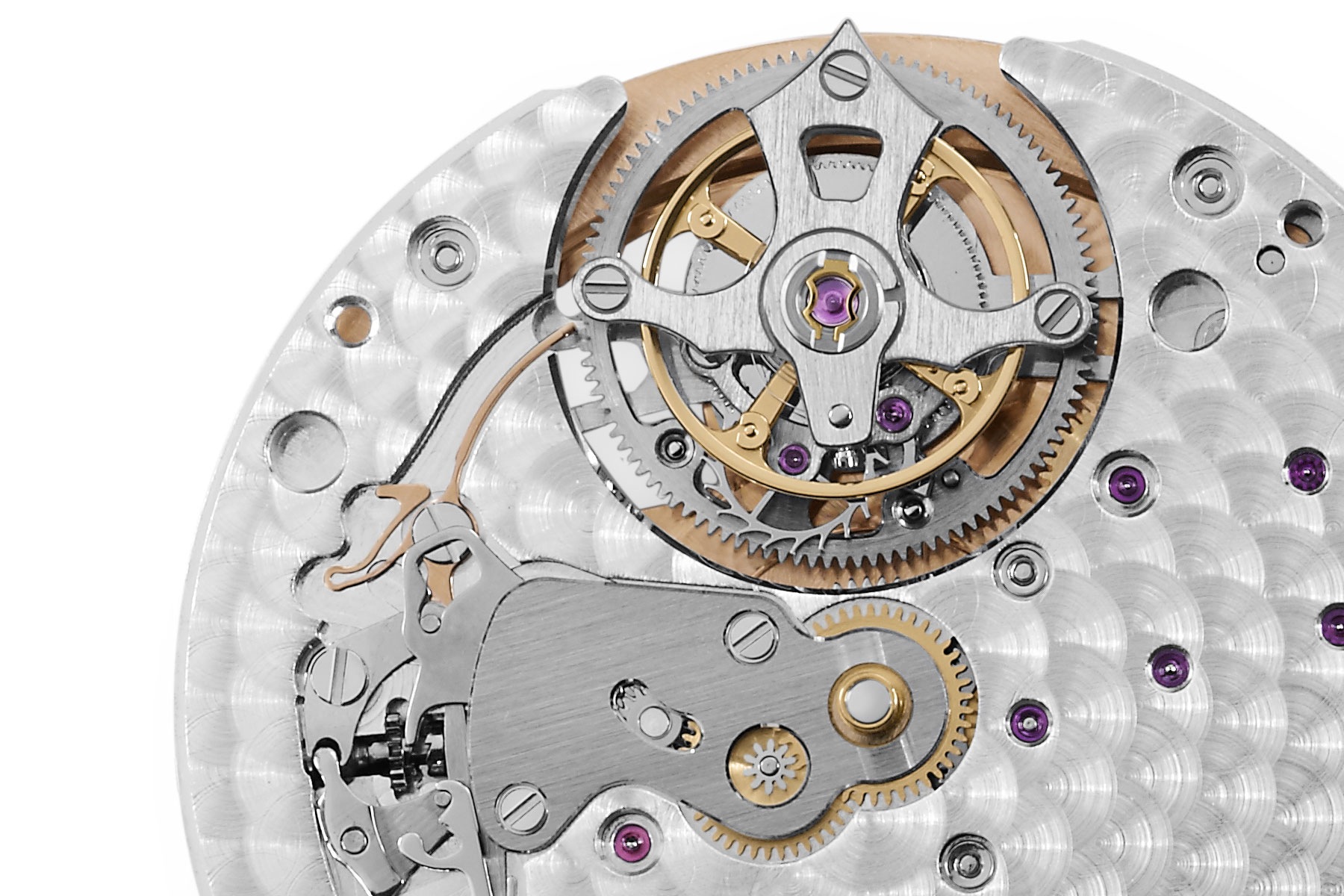

To excel in high-end watchmaking, we have chosen to produce only mechanical movements. With manual or automatic winding, our movements are part of the daily life of their wearers for the long term.

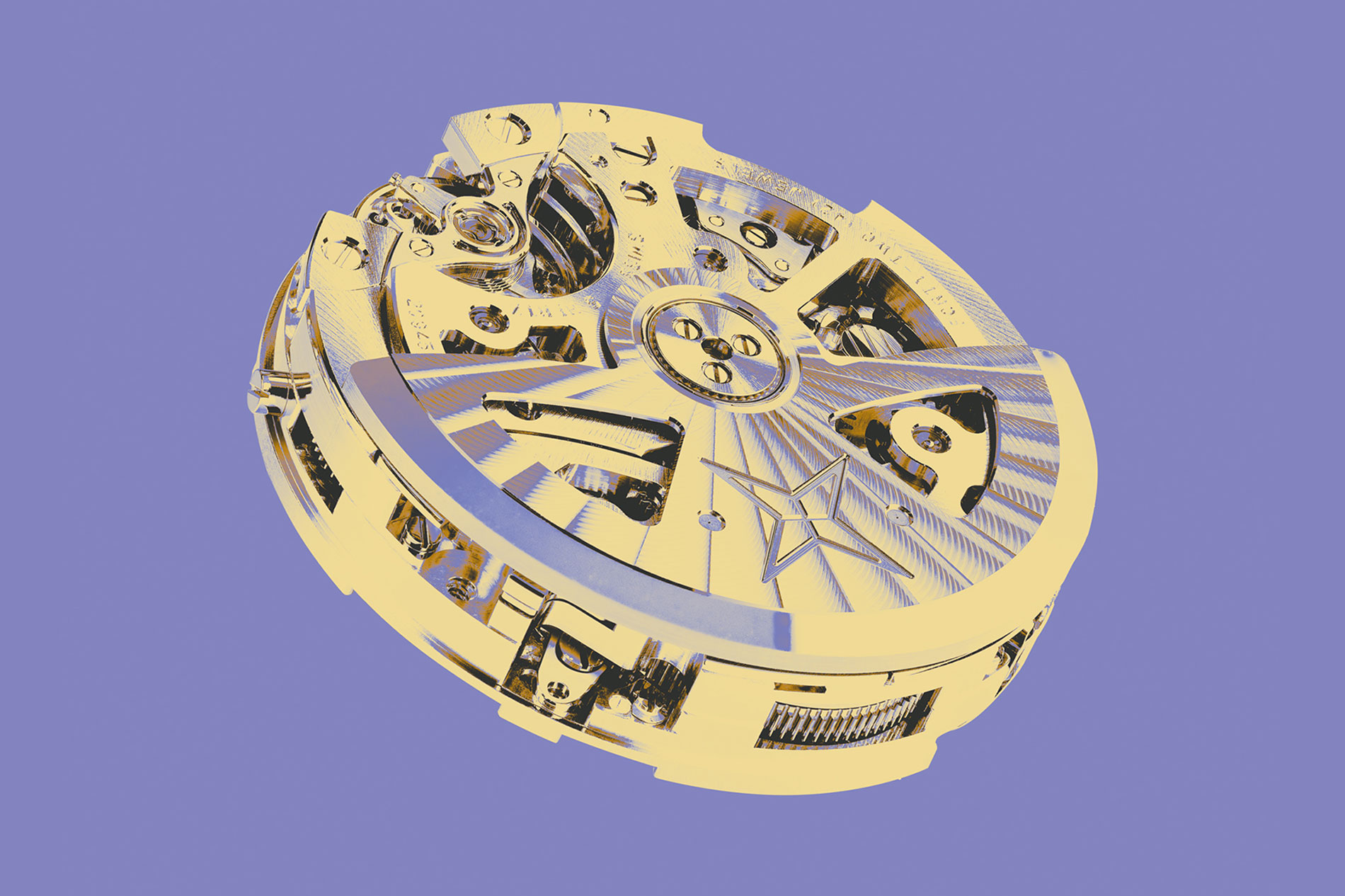

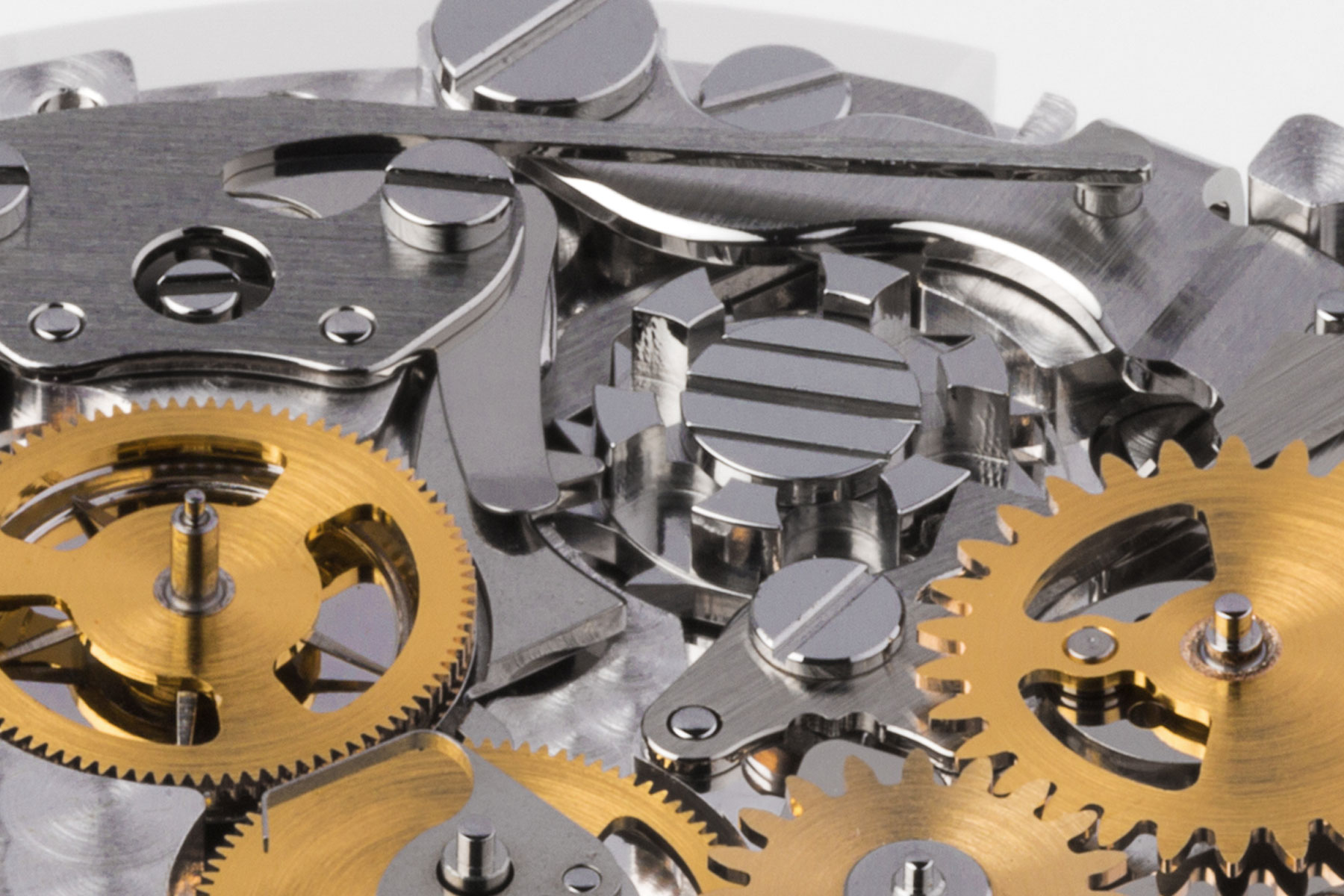

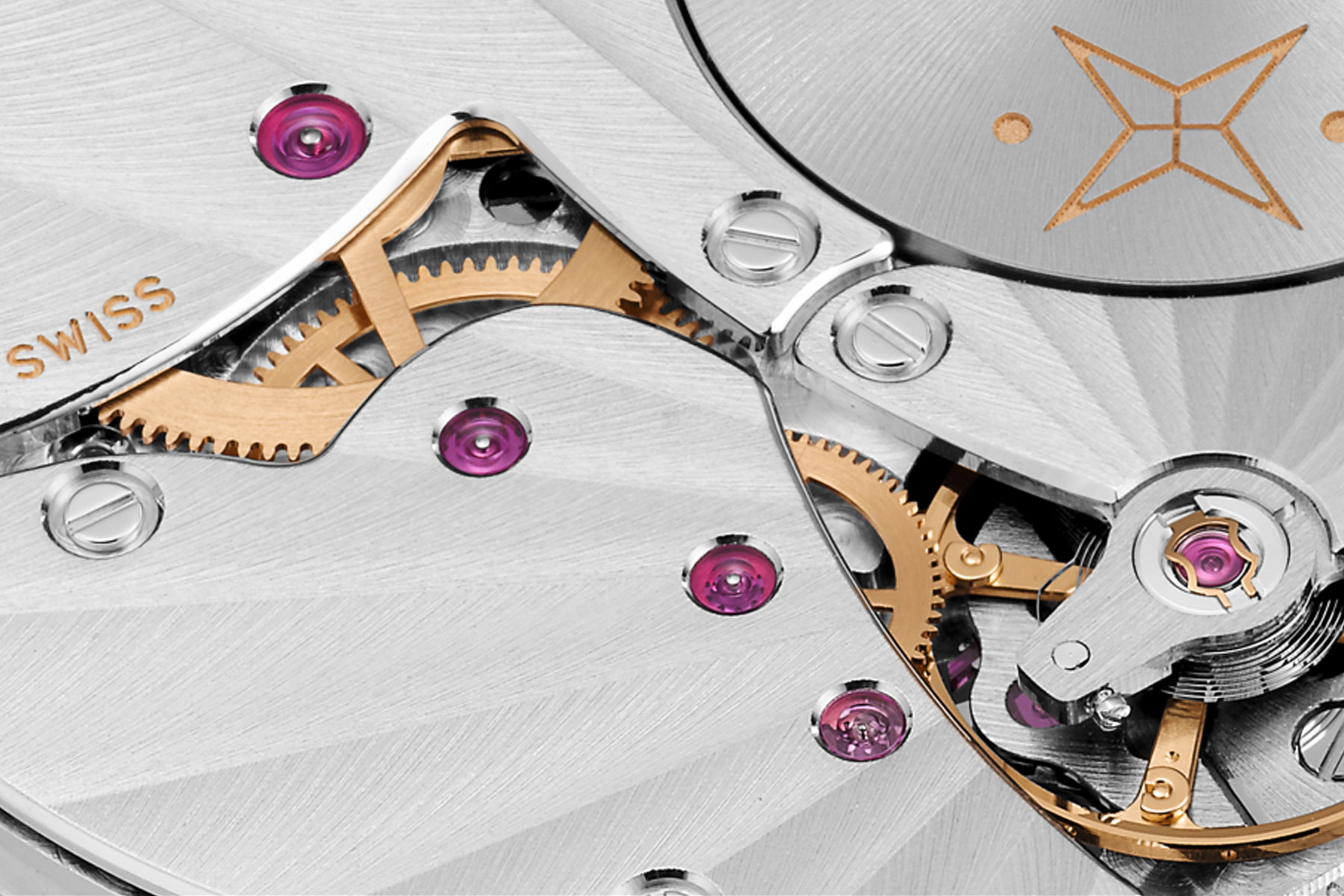

Thanks to their aesthetic finishes, our movements are also the pride of their wearers. Through the open back of the watch case, they can enjoy the permanent spectacle they offer of the effects of the play of light combined with the rigorous complexity of the mechanism.